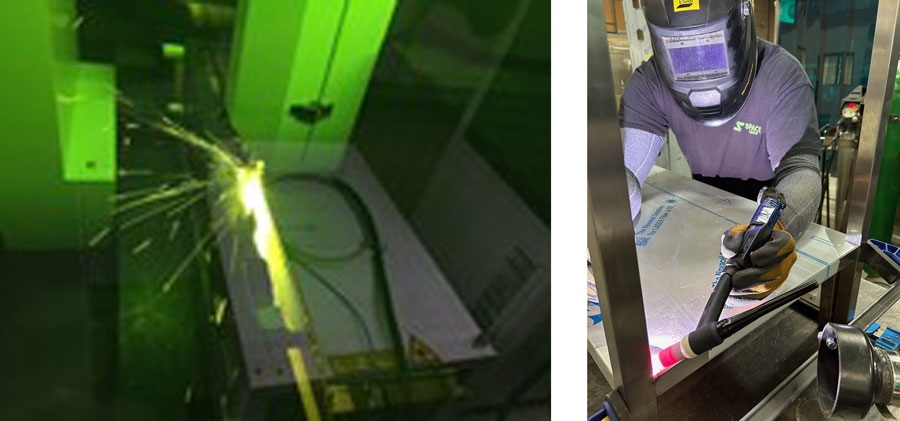

Stainless Steel Manufacturing & Fabrication for Commercial Kitchens

With years of experience, we are specialists in manufacturing fully-fitted commercial kitchens, bars and servery areas.

Our catering fabrication products include the following:

- Wall benches

- Commercial sink units

- Wall shelves

- Ambient over shelves

- Centre benches

- Pot racks / Racking units

- Dishwash tabling

- Wall & Floor cupboards

- Hot cupboards

- Heated pass units

- Stainless steel bars

- Custom servery counters

- Bars

- Front bars

- Back Bars

- Under Bars

- Cocktail Bars

- Coffee Bars

- Breakfast Bars

As well as being durable, our fabricated bars can integrate equipment, utilities and fittings such as glass washers, bottle displays, ice wells, speed rails, electrics, beer lines, waste, coffee knockout, foot rails, and LED lighting to enhance operation and appearance.

Designers choose our manufacturing services to create customised, food-grade products for all kinds of commercial catering, including restaurants, cafeterias, coffee shops and even cruise ships.

The Perfect Solution for Catering Designs

Professional fabrication for your commercial catering designs.

Our engineers are happy to advise on suitable materials for your specified layout, functional designs and budget. We manufacture all components of commercial catering facilities, including pass-throughs, front-of-house counters and back-of-house areas.

Based on your exact measurements and requirements, we manufacture space-efficient stainless steel kitchen units and food servery counters complete with fixtures, electrics, and plumbing.

Installations

Our experienced team can deliver and install your catering equipment, providing a quick, accredited service with fully trained and qualified engineers, including finishing touches such as LED lighting, glass sections, signage and graphics. We can look after installation logistics and documentation as needed.

FAQ’s

What types of venues do you manufacture commercial catering units for?

Every catering business can benefit from our bespoke counters, from casual dining outlets to premium hotels and cruise ships.

Can you help with both the design and manufacture of kitchen units and counters?

Manufacturing and fabrication are our core services, rather than design. However, our experience and supply chain knowledge can support designers with advice on materials and practicalities to help bring a design into reality.

What materials do you offer for counters and worktops?

Back-of-house work areas are manufactured from stainless steel as it is ideal for food preparation, has good corrosion properties and is easy to clean.

Our front-of-house counters are usually manufactured from stainless steel structures, topped and clad with other materials based on aesthetic and usage requirements. These may include quartz stone, Corian, laminate, and/or timber. We have also worked with reclaimed and recycled materials, plastic, and natural stone/marble.

Discuss your material ideas with our team for advice on feasibility.

Can you match existing finishes or branding requirements?

In most cases, matching brand colours and existing finishes is no problem. However, this depends on the materials. In our experience, there can be a noticeable difference between batches of quartz or timber, and ageing and wear can have a marked effect on some materials. In new premises, this isn’t usually an issue, as the existing finish is not present for comparison.

However, for new sections of counter in existing premises, we would advise choosing a contrasting colour/pattern or creating space between the sections to reduce the comparative visual impact of differing finishes.

How long does a commercial kitchen manufacture project usually take?

Usually 4-8 weeks to manufacture from full design approval, depending on size, complexity, materials specified and capacity.

Do you handle installation and site coordination?

Yes, we can offer catering equipment installation to ensure our products are fitted correctly. Contact us to discuss this service.

Can you provide prototypes or visuals before fabrication?

We provide drawings for approval on all our work. Depending on the project, this may be a basic 2D line drawing or a full 3D solid model visual that can be uploaded for use with your other models if required.

Can you advise on health & safety and permits?

We are happy to advise on these important matters. Safety Plan, Risk Assessments, Method Statements and Permits are all essential parts of safe installation and are key aspects of the Contractor’s role under CDM regulations.

We hold the following accreditations ISO45001 Health & Safety Management, Safe Contractor; CHAS; and Constructionline.

Our Accreditations

Holmes is committed to quality, safety, and compliance at every stage of installation. We are accredited and audited by recognised industry bodies. These accreditations demonstrate our commitment to technical competence, health & safety excellence, and professional standards in every installation we deliver.

CATERING EQUIPMENT SOLUTIONS

Have an idea you’d like us to take a look at? Whether it’s a design brief, mood board, layout drawing, CAD file, 3D visual, or even a hand-drawn sketch, feel free to send it over – we’re always happy to review it.

Tel: +44 (0) 1759 375500

Email: sales@hce.co.uk